Services

A series of services dedicated to reduce total acquisition costs and working capital

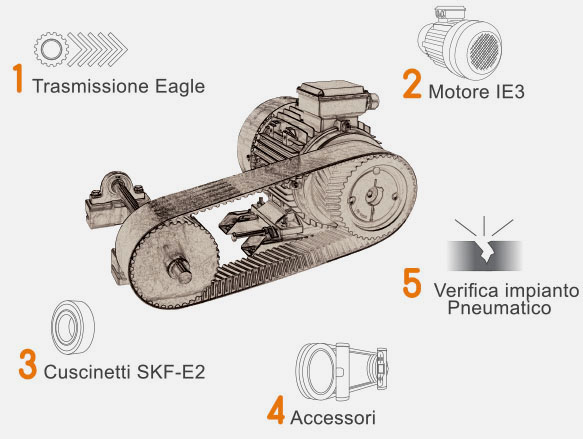

SMART ENERGY PACK

A brand new tool developed to give concrete energy management solutions to your business

Smart Energy Pack is a brand new tool developed to give concrete energy management solutions through 5 key-points

EAGLE TRANSMISSION TOOTHED BELT

The need of compact and reliable power transmission has resulted in the development of new technical solutions based on innovative and increasingly efficient materials. The self-aligning feature reduces diameter, width and weight of the belts, without compromising its strength and granting operation at temperatures over 90° C

IE3 MOTOR

Electric Motors represent the main electric load within the community, where engines are employed in production processes. The systems where these engines operate represent approximately 70% of the energy consumed by the industry. One of the main factors driving energy savings policy is the use of IE3 Motors

SKF-E2 BEARINGS

SKF-E2 Bearings are featured with a revolutionary shield. The DGBB E2 help reducing by 30% friction losses, compared to the SKF Explorer series. Moreover, E2 version increased the operating life-cycle granting better energy efficiency applications through the reduction of power losses

SETUP & TESTING ACCESSORIES

The TKSA20 laser alignment system is an easy tool developed for the shafts alignment. Compared to the traditional methods, in this way no additional calculations are required

PNEUMATIC SYSTEM CHECKING

Qualified personnel will make a complete inspection of your pneumatic circuits The evaluation of the unnecessary consumption of compressed air will quantify the planning of remediation. Thanks to the work on the plants you will get the achievement of the best possible energy efficiency

CONDITION MONITORING

Once the Condition Monitoring tasks have been carried out, the service broadens out in two steps: analysis and intervention

The Condtion Monitoring Service is a predictive maintenance program that aims to significantly increase productive capabilities by combining both strong and cogent sectoral knowledge and the availability of cutting-edge solutions by SKF, thus reducing the risk of halt of economic resources.

Condition Monitoring tasks such as the vibration analysis represent the key points of the predictive maintenance program, allowing the user to collect valuable data about the criticality and nature of any issue.

Once the Condition Monitoring tasks have been carried out, the service broadens out in two steps: analysis and intervention

Benefits: